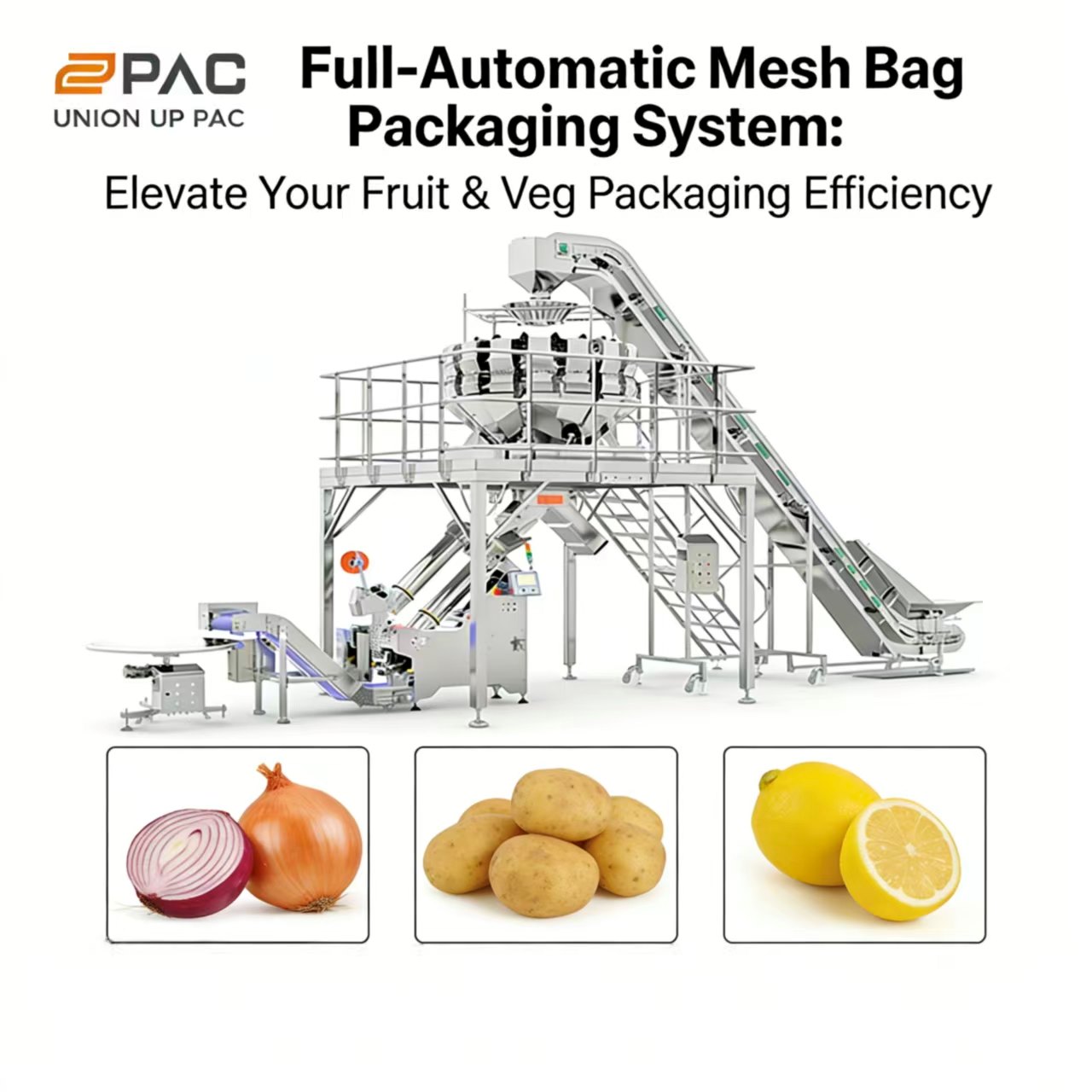

En el sector de productos frescos, un envasado lento o inconsistente no solo representa una ineficiencia, sino una amenaza directa para sus resultados. El envasado manual presenta dificultades con la velocidad, la uniformidad y la protección de productos delicados como las patatas, las cebollas y el ajo. Para asegurar su ventaja competitiva, necesita un sistema de envasado diseñado para las demandas modernas. Ahí es donde UUPAC... Fully-Automatic Mesh Bag Packaging System comes in.

1.Why the Fruit & Veg Industry Needs a Full-Automatic Mesh Bag Packaging System?

For growers, distributors, and processors, the challenges of traditional packaging are all too familiar:

UUPAC's Full-Automatic Mesh Bag Packaging System addresses all these pain points—turning inefficiency into productivity and uncertainty into reliability.

2. Core Features of UUPAC's Mesh Bag Packaging System: Built for Efficiency & Durability

Designed with the unique needs of the fruit and vegetable industry in mind, our automatic system combines robust construction, smart technology, and user-friendly operation. Here's what sets it apart:

1. Food-Grade, Corrosion-Resistant Construction

Safety and hygiene are non-negotiable when packaging fresh produce. Our machine is crafted with 304/316 stainless steel and rigid carbon steel plates, ensuring compliance with food safety standards while delivering exceptional corrosion resistance. Whether you're working in humid packing houses or handling moisture-rich produce like citrus or tomatoes, this system stands up to harsh conditions—guaranteeing long-term reliability.

2. Uninterrupted Production with Full-Automatic Design

The system features a double-cylinder design that allows alternating mesh bag feeding, so the machine runs continuously without stopping to reload. Additionally, the integrated tube automatically replaces used mesh bags, eliminating manual intervention and keeping your line moving. With a packaging speed of 25-40 bags per minute (BPM) (up to 50 BPM for specialized models), it outperforms manual labor by 5-8 times—helping you tackle high-volume orders with ease.

3. Engineered for Precision & Consistency

Consistency is key to building customer trust. Our system uses a combination of two positioning gears and proximity switches to ensure precise net bag placement, while the Schneider PLC and LS inverter deliver stable, accurate control. The result? Standardized bag sizes, uniform weight distribution (from 0.5kg to 5kg), and neat, professional clipping—no more lopsided bags or uneven fills. The intuitive touchscreen interface makes it easy to adjust settings, so your team can master operation in minutes.

4. Durable Components for Long-Term Performance

We believe in building equipment that lasts. The system incorporates top-tier components:

With core components like PLC and MCU at its heart, this system is built to handle the rigors of daily industrial use—reducing maintenance costs and maximizing your return on investment.

Conclusion

Whether you're packaging potatoes, onions, citrus, tomatoes, or other solid materials (including hardware accessories), our system adapts to your requirements. Key flexible features include:

Ready to transform your packaging line? The UUPAC Full-Automatic Mesh Bag Packaging System delivers the triple advantage you need: drastically reduced labor costs, significantly higher output, and guaranteed package consistency.

This is more than a machine—it's your strategic edge. Don't let inefficient packaging limit your growth. Join industry leaders worldwide who trust UUPAC.

Contact us today to schedule a consultation and see how a efficient system can elevate your entire operation.